Rohm starts piezoelectric MEMS foundry service

Rohm Co., Ltd. has started a foundry service for fabricating microelectromechanical systems (MEMS) integrating thin-film piezoelectric element technology, which the company claims is the first such foundry service in the world.

Rohm will provide a comprehensive service extending from wafer pulling to mounting. It is already offering samples and plans to begin volume production at a rate of 2 million units per month in June 2015.

Piezoelectric elements, which possess the inherent property of generating a voltage when pressure is applied, are incorporated in various electronic devices, ranging from inkjet printheads to infrared cameras and autofocus mechanisms of digital cameras.

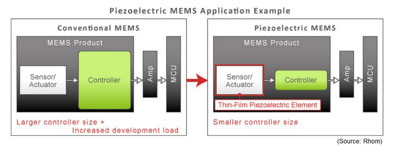

Combining these piezoelectric elements with MEMS devices, which are commonly used in accelerometers and gyroscopes, makes it possible to simplify design and reduce the size of processing controllers, thereby contributing to higher performance, lower costs, and advances in end-product miniaturization. In addition, the energy-saving characteristics of the piezoelectric element itself, which requires very little power during standby, are attracting growing interest.

The fabrication of MEMS with piezoelectric elements requires sophisticated technologies, including deposition of thin films that possess superior piezoelectric properties, precision fabrication and molding of micropiezoelectric elements, and precise alignment with the MEMS drive block.

To overcome these challenges, Rohm collaborated with Professor Isaku Kanno of Kobe University's Graduate School of Engineering on evaluation measurement methods for thin-film piezoelectric elements, and leveraged Rohm Group's prowess in production technologies, particularly ferroelectric technology and MEMS technology. Rohm established volume-production technology for piezoelectric MEMS.

Rohm has already started joint development of piezoelectric MEMS products with customers. The company intends to target diverse applications, including wearable devices and industrial-use inkjet printers. Starting with production on a 6-inch wafer line, Rohm plans to shift to an 8-inch line as demand expands.

Press release:

Integrated manufacturing system, from development and production to mounting, customizable to user needs New MEMS Foundry Business

The original article in Japanese appeared in the Aug. 20 issue of The Semiconductor Industry News. Translation by EmergingTech, which added the figure.

Warning: Invalid argument supplied for foreach() in /home2/semicon/hosting/spiwww/include/Banner.php on line 78

Warning: array_multisort(): Argument #1 is expected to be an array or a sort flag in /home2/semicon/hosting/spiwww/include/Banner.php on line 81

Warning: Invalid argument supplied for foreach() in /home2/semicon/hosting/spiwww/include/Banner.php on line 85